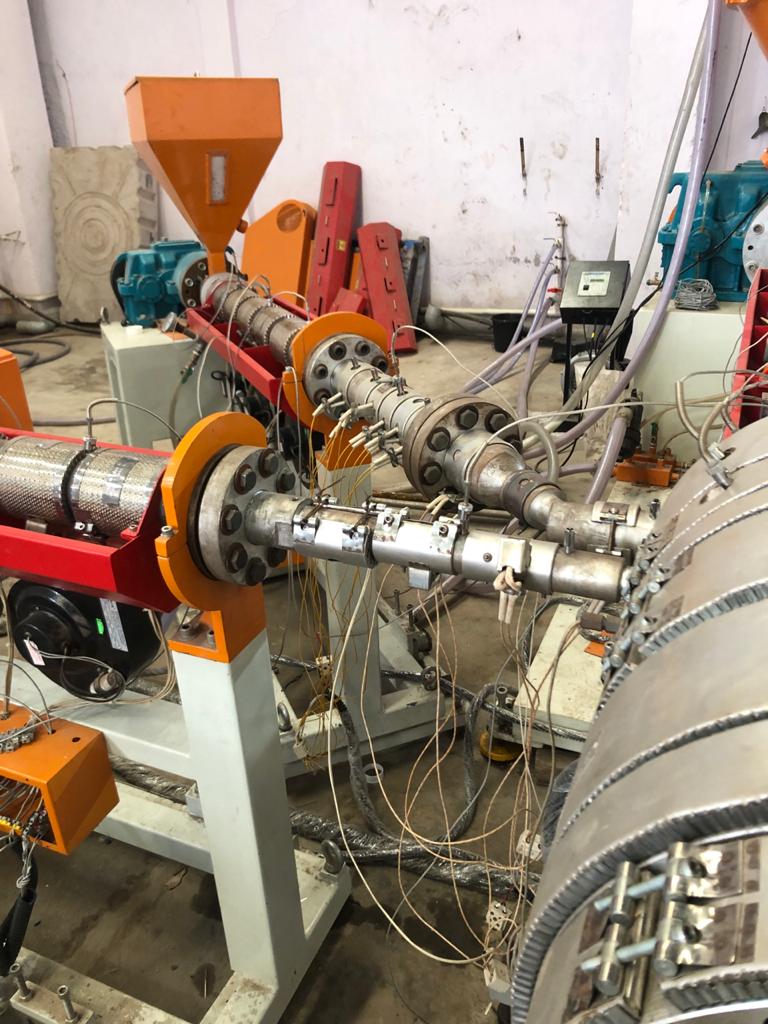

Inner Coating Extruder

The Next Generation Extruders. Screw and Barrel are Designed and developed such a way that it can match specific raw material and end product requirement. RCV engineering Offers barrier screws a resulting higher output low,melttemperature and Good quality of melt.

Features

- Extruder with 4th Generation energy efficiecy

- Direct coupled design ensures minimum transmission loss

- Wear resistant coating ensures long screw life and high rpm

- Low power consumption upto 0.29 KWH/Kg

- Same extruder can extrude PPR too

- Grooved Feed Extruders

Single Screw Extruders for Co-extrusion

| Models | Unit | CEMS 25 | CEMS 40 | CEMS 50 | CEMS 65 | CEMS 75 | CEMS 90 | CEMS 120 |

|---|---|---|---|---|---|---|---|---|

| ExtruderOrive | KW | 3.1 | 7.5 | 15 | 30 | 37.5 | 60 | 110 |

| LO Ratio | RPM | 24:1 | 26:1 | 26:1 | 26:1 | 26:1 | 26:1 | 26:1 |

| OutPut | Kg/Hr | 4-5 | 18-20 | 36-40 | 90-100 | 120-130 | 170-190 | 300-320 |

| Screw Dia | MM | 25 | 40 | 50 | 65 | 75 | 90 | 120 |